Save 10% OFF All Subscription Orders.

Save 10% OFF All Subscription Orders.

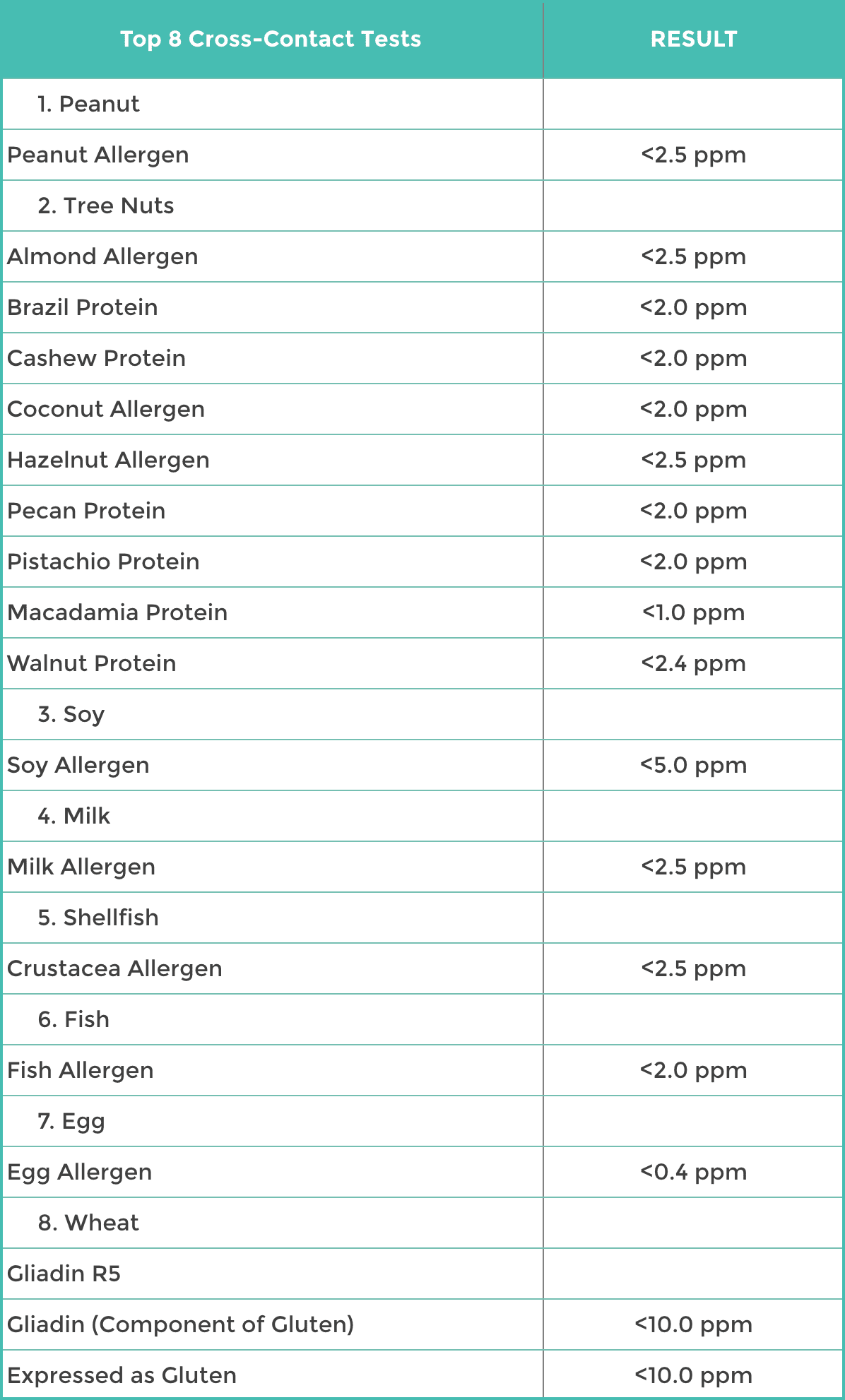

OWYN protein powders are produced with the highest industry standards to ensure no cross-contact with any top 9 allergen.

Smart Sourcing

Ingredient suppliers are required to provide OWYN’s contract manufacturer with allergen statements, product data specifications, and information about the processing of each ingredient.

OWYN's contract manufacturer qualifies suppliers based on historical allergen testing performance data, and has obtained Letters of Continuing Guarantee attesting that their supplier’s ingredients have no cross-contact with any Top 9 allergen.

OWYN's contract manufacturer periodically conducts on-site food allergy safety and quality audits of ingredient suppliers to ensure compliance with Good Manufacturing Practices (GMP) and HACCP (food safety control) certification programs.

SEGREGATE, SANITIZE, TEST.

Our contract manufacturer maintains a comprehensive sanitation and allergen testing protocol for milk, soy, wheat, egg, tree nuts (almond and walnuts only), fish and shellfish, which comprise the scope of the top 9 allergens present in the plant. The plant does not process peanuts.

Testing

Our contract manufacturer tests ingredients for the presence of Top 8 allergens using a skip lot testing method. Testing is conducted by accredited 3rd party laboratories using Enzyme-Linked ImmunoSorbent Assay (ELISA) testing procedures. Tests are done on milk, soy, egg, wheat, peanut, fish, shellfish and tree nuts (almond and walnut only).

Isolation

The potential for cross-contact is minimized by isolating the production of allergen-containing products from non-allergen products. All production areas and equipment utilizing allergens are clearly identified with signs stating, "Allergen in Use", and personnel who are exposed to allergens are restricted to those production areas and prevented from entering non-allergen areas.

Sanitize

All blending and filling equipment contact surfaces receive a validated detergent wash followed by a sanitation protocol preceding each manufacturing run. All production rooms and ancillary areas are cleaned and sanitized according to the same qualified protocol.

Verification

Quality Assurance technicians verify the absence of top 8 allergens from product contact surfaces on equipment and utensils using allergen test swabs. Production room and equipment usage are not permitted until QA verifies that no allergen residues remain.

Documentation

All tests are documented and maintained as part of each product's batch record.

Best Practices in Contract Manufacturing.

The blending process is the most vulnerable to allergen cross-contact as containers of ingredients are opened only during this step. All other processing and filling steps are done in closed environments.

Blend operators are required to wear full jumpsuits and shoe covers, which are removed and laundered by a certified service following each use.

Our contract manufacturer is certified with the Hazard Analysis and Critical Control Points (HAACP) food safety program that includes an effective Allergen Control Program.

OWYN FINISHED PRODUCT IS INDEPENDENTLY TESTED FOR THE TOP 9 ALLERGENS.

OWYN uses accredited 3rd party allergen testing laboratories to test for the Top 9 allergens.

OWYN maintains a comprehensive electronic database of allergen testing documentation for finished goods lot test results.

OWYN uses baseline allergen thresholds from industry, academic, and governmental sources to establish appropriate detectable amounts for consumption assessment. All of OWYN’s products require a strict gluten-free standard of <10 ppm (vs the FDA’s gluten-free standard of <20 ppm)

*Every lot of finished, reconstituted product is tested for the presence of Top 9 allergens using accredited 3rd party laboratories. OWYN won’t clear final product for shipment until documentation is received verifying that the finished, reconstituted product contains no cross-contact with any Top 9 allergens. Allergen testing is only conducted on powders reconstituted with 9-10oz of water. As with any dry, concentrated powder, allergens may be present even when not detected in the component raw ingredients.